The history and production of maple syrup have their roots before the arrival of the first European settlers in America: the Native Americans, in fact, were already able to collect maple sap and turn it into syrup.

There are many laws about it, some of which have as protagonists even animals.

Maple syrup is made of nature, bicentennial traditions and passion that every year, in spring, are repeated with a ritual cadence.

Production is dictated by the rhythms of nature: the sugar season begins at the end of February and continues until the month of April. The particular climatic conditions of this period favor the outflow of maple sap from the inside of the tree to the outside.

The history of maple syrup

According to some stories, the Amerindians would have observed dogs, or squirrels, lick the maple sap that leaked from the bark and would have imitated them, thus discovering the precious nectar.

Even the production of maple syrup does not lack myths. The most famous of which wants as first producer of maple syrup the wife of a tribal leader. One late winter morning, the woman’s husband went out to hunt for the tomahawk he had driven into the tree the night before. The warm climate of that day began to make the sap flow along the trunk that then went to fill a container placed at the foot of the tree. The woman thinking it was pure water cooked you meat for dinner. The cooking transformed the sap into syrup thus flavoring the dish.

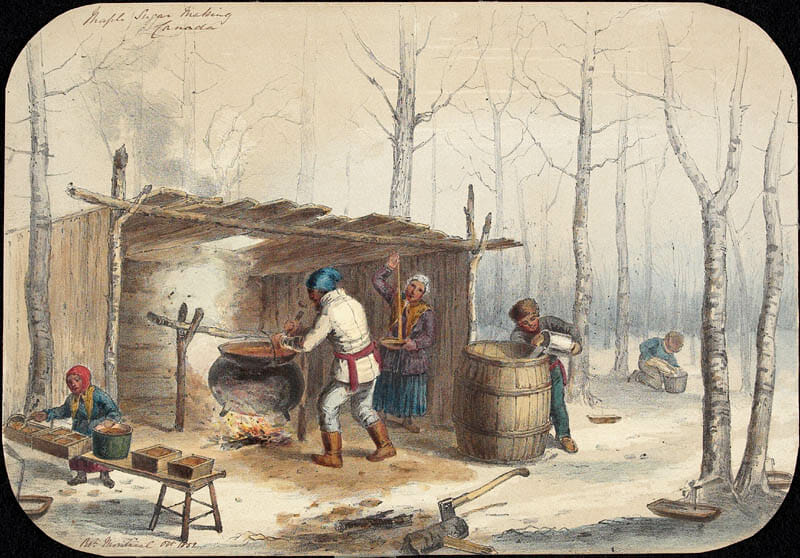

The first methods of collecting Native American sap included a V-shaped cut in the maple bark and the insertion of a piece of wood on the bottom of the cut: the sap would then be leaked from the wooden wedge into baskets placed at the base of the tree. The sap was subsequently collected and boiled slowly by the women of the tribe in terracotta pots, over fires placed under a roof made of tree branches (in practice a sort of ancestor system of the Sugar Shacks o Cabane à sucre or the “huts of the sugar” typical of eastern Canada).

It was the natives who explained to the first settlers how to carve the trunk of the trees in early spring, collect the sap, boil it in iron cauldrons and finally pour it into small wooden moulds of various shapes.

Between the late ‘700 and early ‘800s began the export of maple syrup, in particular to France which saw a great consumption among the nobles and the wealthiest classes.

In the nineteenth century, thanks to scientific advances, there were great changes in the methods of collecting and producing maple syrup: around 1850 iron containers were replaced by two-pan evaporators much more efficient than boilers that allowed to halve the cooking time. In addition, tractors began to take the place of draught animals to carry sap from trees to sugar huts. Until the early 1900s the production of maple syrup took place exclusively at the family level. It was only from the beginning of the twentieth century that a real and own industry. In this period the maple syrup began to spread more and more in supermarkets and was in the 1920s when maple syrup was classified in five categories.

In the 1970s Technical advances allowed manufacturers to use reverse osmosis machines to remove water from the sap before boiling.

Larger, more functional storage containers and preheaters were used to reduce heat loss. Later, the production of maple syrup evolved more and more until the model that is used today.

The production of maple syrup

80% of the production of maple syrup comes from Canada, in particular from the region of Quebec, the most eastern and French-speaking region.

There are about 150 maple species in the world, but only three of them are used for the production of maple syrup: Sugar Maple (Acer saccharum), Black Maple (A. nigrum), Red Maple (A. rubrum). All species must be at least 80 years old before sap is extracted.

Maple syrup is harvested in springwhen the temperature between night and day fluctuates around 0 ºC.

The sap is let out through a small hole in the bark positioned at a height of about 1.5 m from the ground. Through a dense network of small pipes, the sap is then conveyed into a collection tank.

The production of lymph is the result of a physical action caused by a thermal variation of the temperature around 0 ºC. In summer Maple produces sugar through photosynthesis. Sugar feeds the tree’s cellular respiration and promotes its growth; excess sugar is accumulated in the roots in the form of starch.

In spring, the night frost alternating with the diurnal thaw activates the lymphatic flow. During the night the branches cool causing the air contained inside to contract. The sap contained in the branches also freezes, thus increasing its volume. following this difference in volume water rises through the tree, carrying the sugars present in the roots.

During the day, the heat of the sun warms the branches of the tree. The sap then returns From solid to liquid state, the air in the tree fibers expands again. This mechanical action creates a pressure that pushes the sugary sap towards the outside of the trunk of the tree: at this point, the sap is collected in buckets or conveyed in special containers.

The sap conveyed through a dense network of tubes in the collection tray, then enters the evaporator, a kind of large kettle.

As the water evaporates the most concentrated liquid begins to flow out in the next stage, assuming the characteristic amber color.

Depending on the harvest period, the maple syrup takes on a more or less intense color: lighter at the beginning of the season and darker at the end of the harvest period.

Maple sap, which initially consisted of 98% water and 2% sugar, now takes on a composition of 67% sugar.

The syrup thus obtained is filtered and bottled or transferred into special steel barrels.

The production of maple syrup requires only the use of heat for evaporation, therefore no preservatives, dyes, thickeners or added sugars are used.

Depending on the weather, the sugar season lasts from 4 to 6 weeks and each maple tree produces on average 10-12 liters of sap.

To produce a 1 liter carafe of pure maple syrup, very special climatic conditions are therefore needed, 4-6 weeks and a patient work handed down from generation to generation.